Die Casting Customization

-

01

01After-Sales Quality Tracking

Dedicated project engineers provide after-sales support, quality tracking, and continuous improvement for long-term die casting partnerships.

-

02

02Packaging & Global Shipping

Customized packaging solutions and global logistics support safe shipment of die casting components via air, sea, or land freight.

-

03

03Surface Treatment

We provide in-house surface treatment for die casting parts, including anodizing, electroplating, powder coating, painting, electrophoresis, and passivation to enhance durability and appearance.

-

04

04Burnishing & Polishing

Additional polishing or burnishing is applied for Class-A cosmetic die casting parts, especially for automotive, electronics, and consumer products.

-

05

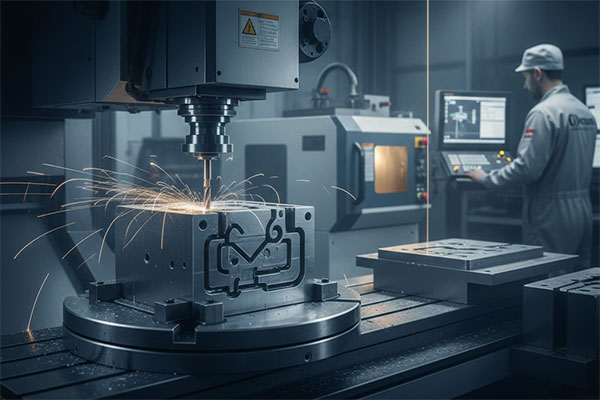

05Precision CNC Machining

Critical functional areas are completed by CNC precision machining, including milling, drilling, tapping, and threading to achieve tight tolerances.

-

06

06Surface Finishing

Initial surface finishing such as deburring, shot blasting, and polishing improves surface quality and prepares parts for further processing.

-

07

07High Pressure Die Casting

Using advanced high pressure die casting machines, molten alloy is injected into steel molds to produce dense, high-precision die casting parts with stable repeatability.

-

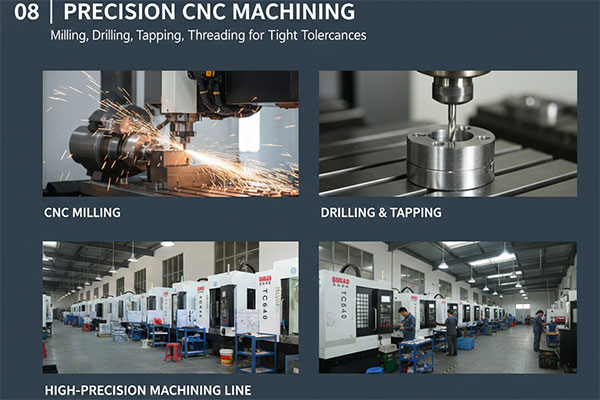

08

08Die Casting Mold Manufacturing

As an in-house die cast mold manufacturer, we produce high-precision molds using CNC machining, EDM, and wire cutting, ensuring long mold life and dimensional accuracy.

-

09

09Die Casting Customization Inquiry

Customers provide drawings, samples, or technical requirements for custom die casting parts, including aluminum die casting, zinc die casting, and magnesium die casting components.

-

010

010Die Casting Process Evaluation

Our engineering team conducts a full die casting feasibility analysis, including product structure, wall thickness, alloy selection, and design for manufacturing (DFM) optimization to ensure stable mass production.

-

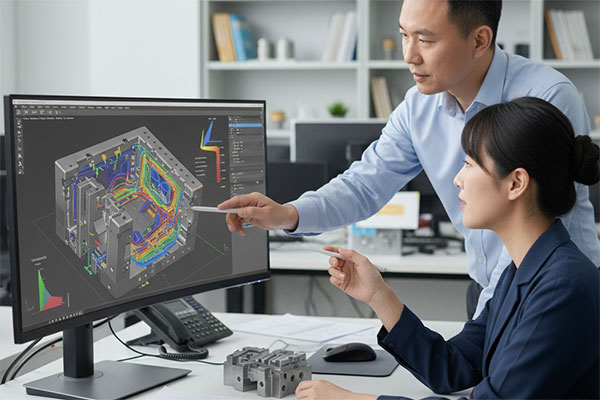

011

011Die Casting Mold Design

Experienced mold engineers carry out die casting mold design using 3D modeling and mold flow simulation to optimize gate design, runner systems, venting, and cooling efficiency.

-

012

012Raw Material Inspection

All aluminum, zinc, and magnesium alloy materials undergo strict incoming quality inspection to ensure chemical composition, mechanical properties, and production consistency.