Automotive Center Display Heat Dissipation Housing

| Item | Specification |

|---|---|

| Product Name | Automotive Center Display Heat Dissipation Housing |

| Material | Aluminum Alloy (ADC12 / A380) |

| Manufacturing Process | High Pressure Die Casting (HPDC) |

| Structure | One-Piece Integrated Housing with Cooling Fins |

| Thermal Conductivity | ≥ 100 W/(m·K) |

| Machining | CNC Machining (Mounting & Functional Areas) |

| Surface Treatment | Anodizing / E-Coating / Insulating Coating |

| Wall Thickness | Thin-Wall Design (Customized) |

| Dimensional Tolerance | ±0.05 mm (Critical Areas Tighter) |

| Vibration Resistance | Automotive Grade |

| Operating Environment | Vehicle Interior Electronics |

| Quality Standard | IATF 16949 / ISO 9001 |

| Customization | OEM / ODM Supported |

| Application | Automotive Center Display / Smart Cockpit Systems |

Description

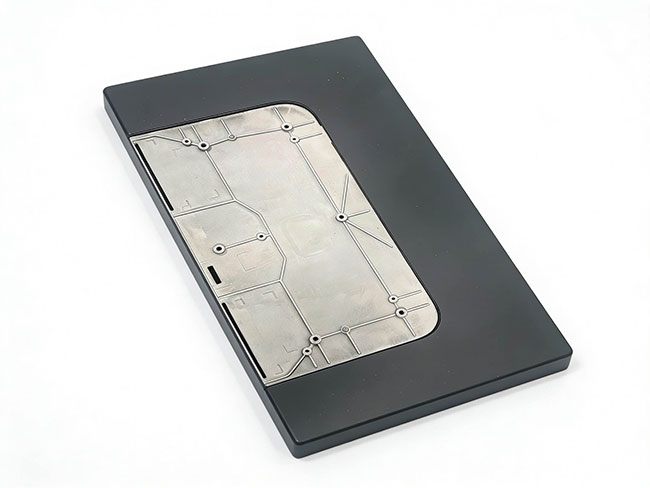

The automotive center display heat dissipation housing is a high-performance thermal management and structural support component specifically designed for in-vehicle center screens. Manufactured through one-piece high-pressure die casting, it achieves an optimal balance between efficient heat dissipation, structural stability, and lightweight design, making it a core foundational component of modern smart cockpit electronic systems.

By integrating thermal and structural functions into a single die-cast part, the housing enhances system reliability while supporting compact packaging and long-term durability under automotive operating conditions.

Material & Manufacturing Process

The housing is produced using high-strength aluminum alloys such as ADC12 or A380, selected for their excellent thermal conductivity, vibration resistance, and lightweight characteristics.

A high-pressure die casting (HPDC) process is applied to form the housing in one piece, followed by precision CNC machining and automotive-grade surface treatment. This combination ensures tight dimensional tolerances, consistent quality, and reliable functional performance.

Key Design Features

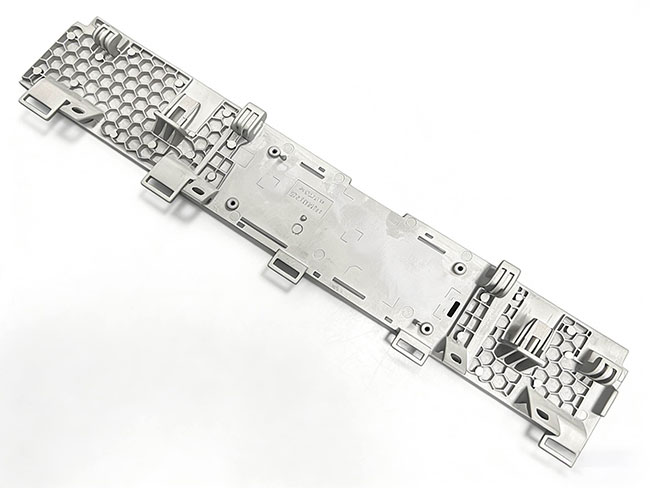

Integrated Cooling Fins

Dense fin structures maximize heat dissipation area, allowing rapid transfer of heat generated by the center display. This effectively prevents performance issues such as screen lag, blackouts, or premature electronic aging caused by overheating.

High-Precision Mounting Structure

Pre-designed positioning holes, slots, clips, and threaded interfaces ensure accurate assembly with display modules and infotainment frames, maintaining structural stability under continuous vehicle vibration.

Lightweight Optimization

Through topology optimization and thin-wall die casting design, the housing reduces overall weight while maintaining required mechanical strength.

Corrosion Protection & Electrical Insulation

Optional anodizing, electrophoretic coating, or insulating coatings enhance corrosion resistance and meet electrical safety requirements for automotive electronics.

Performance Advantages

Efficient Thermal Management

Thermal conductivity ≥ 100 W/(m·K), keeping core display temperatures within safe operating ranges and extending component lifespan.

High Structural Reliability

Excellent impact and vibration resistance, compliant with automotive-grade durability and road test requirements.

Strong Customization Capability

Custom-designed to match different vehicle models, display sizes, and layouts, compatible with mainstream infotainment chips and display modules.

Automotive Compliance

Manufactured under IATF 16949 certified quality systems, meeting RoHS and REACH environmental regulations.

Applications

Widely used in new energy vehicles and intelligent connected vehicles, including:

Automotive center display screens

Passenger entertainment displays

Smart cockpit and infotainment systems

This component plays a key role in improving system stability, thermal performance, and user experience inside modern vehicle cabins.