Die-Cast Housing Factory for Automotive Electronic Control Units (ECUs)

| Item | Specification |

|---|---|

| Product Name | Automotive ECU Die Casting Housing |

| Manufacturer Type | Die Casting Factory |

| Application | Automotive Electronic Control Unit (ECU) |

| Material | Aluminum Alloy (ADC12 / A380) |

| Casting Process | High Pressure Die Casting |

| Post Processing | CNC Machining |

| Structural Function | Protection, Mounting, Support |

| Dimensional Tolerance | ±0.05 mm (Critical Areas) |

| Vibration Resistance | Automotive Grade |

| Weight Optimization | Topology Optimized |

| Surface Treatment | As-cast / E-Coating / Powder Coating (Optional) |

| Quality System | IATF 16949 / ISO 9001 |

| Customization | OEM / ODM Available |

Description

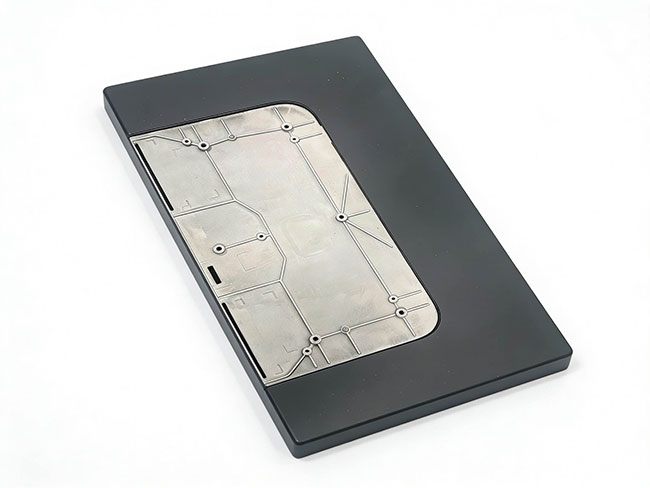

Integrated die-cast protective and mounting housings specifically designed for in-vehicle electronic control units (ECUs). Manufactured using high-strength aluminum alloy die-casting technology, these housings provide structural support, physical protection, and precise mounting reference points for core control modules. They serve as critical structural components ensuring the stability and reliability of in-vehicle electronic systems.

Core Materials and Processes

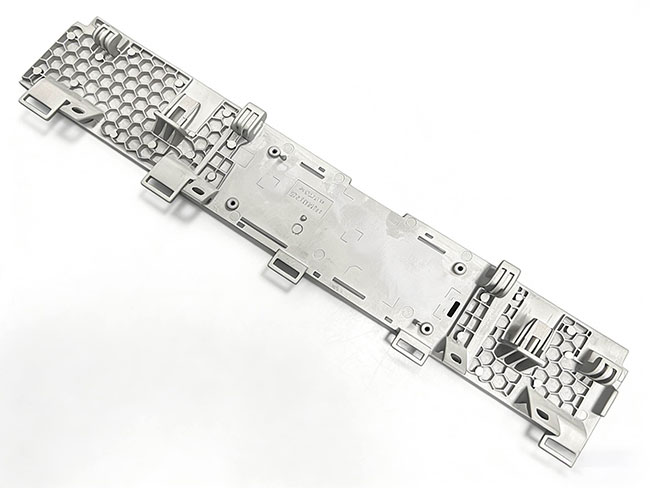

Material: High-strength aluminum alloys (e.g., ADC12/A380) selected to balance structural strength, vibration resistance, and lightweight requirements.

Process: High-pressure die-casting for monolithic forming, complemented by precision CNC machining to ensure dimensional accuracy and consistency of mounting holes and module interfaces.

Key Design Highlights

Integrated Mounting Layout: Features multiple square and irregular cutouts for direct integration of control chips, interface modules, and connectors, enabling high-density assembly.

Precision Positioning Interfaces: Pre-set threaded holes, locating pins, and snap-fit mechanisms ensure accurate alignment of control units, meeting automotive-grade assembly tolerances.

Enhanced Physical Protection: Monolithic frame structure effectively resists impacts and vibrations, safeguarding internal precision electronic components.

Weight Optimization: Topology-optimized design reduces component weight while maintaining strength, contributing to vehicle lightweighting.

Performance Advantages

High Integration: Significantly reduces part count, simplifies assembly, and lowers vehicle cost and weight.

Robust Reliability: Withstands rigorous vibration, shock, and endurance testing for complex driving conditions.

Comprehensive Protection: Provides stable physical support and shielding for internal electronics, enhancing system immunity to interference.

Customizable Adaptation: Tailored development for diverse vehicle control unit architectures, compatible with mainstream automotive electronics platforms.

Application Scenarios

Widely deployed in new energy vehicle powertrain control systems, smart cockpit infotainment systems, and various driver assistance modules. This component is pivotal for enhancing the integration, reliability, and user experience of automotive electronic systems.