VC Vapor Chamber Integrated Housing for Automotive Center Display

| Item | Specification |

|---|---|

| Product Name | VC Vapor Chamber Integrated Housing |

| Application | Automotive Center Display / Smart Cockpit |

| Housing Material | Aluminum Alloy (ADC12 / A380) |

| VC Material | Copper / Aluminum Composite |

| Cooling Technology | Vapor Chamber Phase-Change Cooling |

| Manufacturing Process | HPDC + CNC Machining |

| VC Integration Process | Vacuum Brazing / Diffusion Bonding |

| Thermal Performance | 3–5× higher than conventional metal heat sinks |

| Dimensional Tolerance | ±0.05 mm (Critical Areas) |

| Surface Treatment | Powder Coating / E-Coating (Optional) |

| Vibration Resistance | Automotive Grade |

| Quality System | IATF 16949 / ISO 9001 |

| Customization | OEM / ODM Supported |

Description

The VC vapor chamber integrated housing for automotive center displays is a high-performance thermal management and structural solution specifically designed for large-size, high-power automotive displays in new energy vehicles.

By integrating vapor chamber phase-change cooling technology with a die-cast aluminum structural housing, this component effectively solves heat dissipation challenges while providing reliable mechanical support, ensuring long-term system stability.

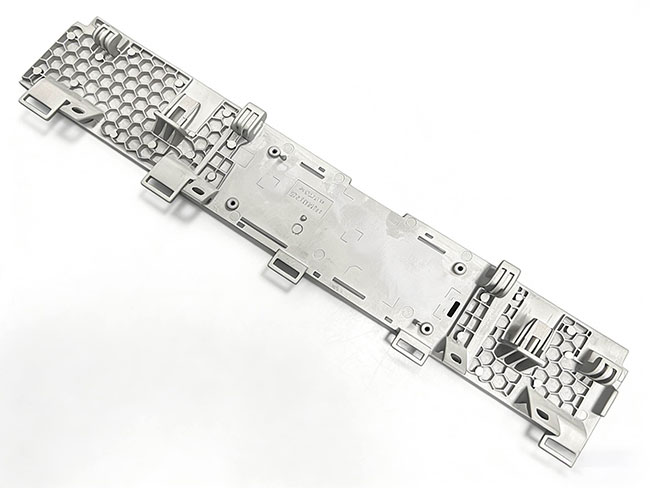

Material & Manufacturing Process

Material Composition

Housing:

High-strength aluminum alloy such as ADC12 / A380, manufactured by high-pressure die casting, offering excellent structural rigidity, vibration resistance, and lightweight performance.

Vapor Chamber (VC):

Copper or aluminum-based composite vapor chamber with internally sealed working fluid, enabling efficient phase-change heat transfer.

Manufacturing Process

High Pressure Die Casting (HPDC) for one-piece housing formation

Precision CNC machining to ensure flatness and tight interface tolerance between housing and VC

Vacuum brazing or diffusion bonding to achieve seamless integration between the vapor chamber and the aluminum housing

Key Design Features

High-Efficiency VC Cooling Technology

The internal working fluid undergoes continuous phase-change circulation in a vacuum environment, rapidly spreading heat across the entire housing.

Compared to traditional metal heat sinks, thermal efficiency is improved by 3–5 times, keeping high-power chips within a safe operating temperature range.

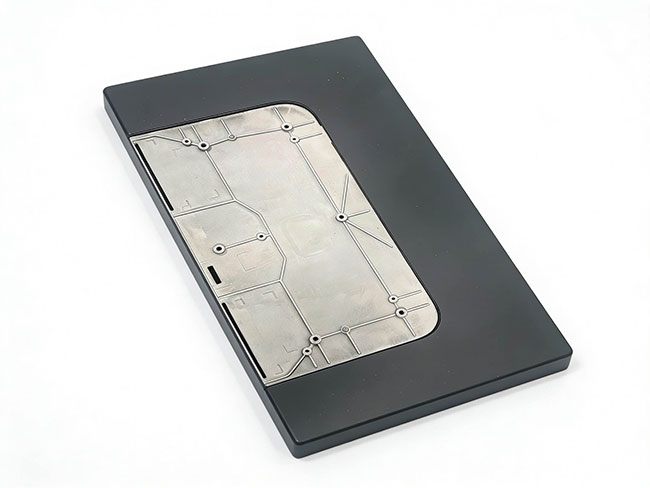

Integrated Structural Design

Combines cooling core and mounting structure into a single component, reducing part count, simplifying assembly, and lowering overall system weight.

High-Precision Mounting Interfaces

Pre-configured positioning holes, clips, and threaded holes allow direct and accurate integration with display modules and infotainment frames, ensuring stability under vehicle vibration conditions.

Automotive-Grade Surface Treatment

Optional matte black powder coating or electrophoretic coating provides corrosion resistance while maintaining a premium interior appearance consistent with vehicle cabin design.

Performance Advantages

Extreme Heat Dissipation Capability

Effective thermal conductivity far exceeds conventional aluminum housings, preventing display lag, black screen issues, and premature electronic aging caused by overheating.

Structural Reliability

Validated through strict vibration, impact, and durability testing to ensure stable performance throughout the vehicle lifecycle.

Lightweight & Efficient

Integrated design achieves optimal performance while minimizing component weight, supporting overall vehicle lightweighting strategies.

Customizable Design

Tailored according to display size, layout, and chip power consumption, compatible with mainstream automotive infotainment platforms.

Typical Applications

Widely applied in:

New energy vehicle center displays

Passenger-side entertainment screens

Smart cockpit infotainment systems

This VC integrated housing is a key enabling component for enhancing thermal stability, system reliability, and user experience in advanced automotive interiors.