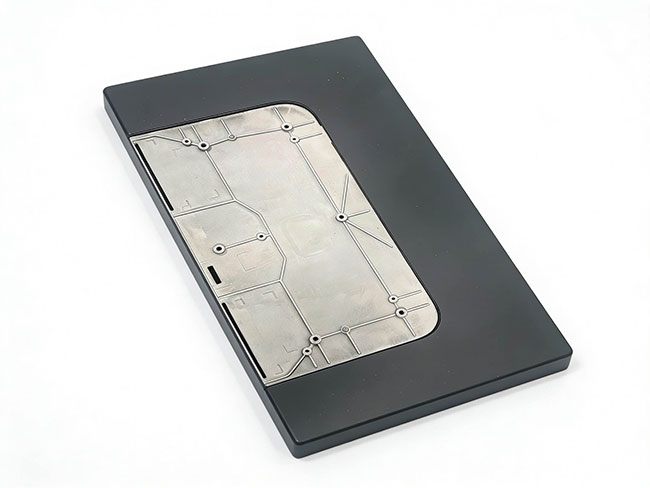

Integrated Die-Cast Bracket for Automotive Center Display

| Item | Specification |

|---|---|

| Product Name | Integrated Die-Cast Bracket for Automotive Center Display |

| Material | Aluminum Alloy (ADC12 / A380) |

| Manufacturing Process | High Pressure Die Casting (HPDC) |

| Structure | One-Piece Integrated Bracket |

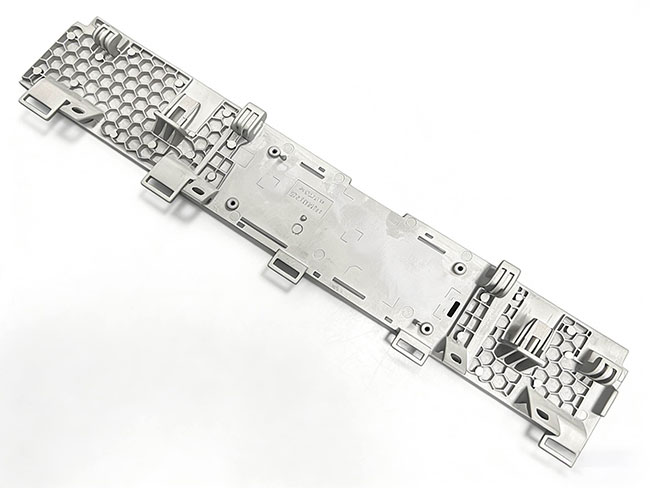

| Design Feature | Honeycomb Lightweight Structure |

| Machining | CNC Machining (Critical Mounting Areas) |

| Dimensional Tolerance | ±0.05 mm (Critical Areas Tighter) |

| Vibration Resistance | Automotive Grade |

| Surface Treatment | Anodizing / E-Coating / Powder Coating (Optional) |

| Quality Standard | IATF 16949 / ISO 9001 |

| Customization | OEM / ODM Supported |

| Application | Automotive Center Display & Smart Cockpit |

Description

The automotive integrated die-cast center display bracket is a core structural component designed for next-generation smart cockpit systems. Manufactured using one-piece aluminum alloy high-pressure die casting, the bracket integrates structural support, lightweight optimization, and precise installation positioning into a single component, ensuring long-term stability and reliability of large in-vehicle displays.

Material & Manufacturing Process

Material: High-strength aluminum alloys such as ADC12 / A380, providing an optimal balance of lightweight performance, vibration resistance, and structural rigidity.

Process: High-pressure die casting (HPDC) combined with precision CNC machining, ensuring dimensional accuracy and assembly consistency for complex integrated structures.

Key Design Features

Honeycomb Lightweight Structure

Large-area honeycomb hollow design significantly reduces component weight while maintaining automotive-grade strength and stiffness, contributing to overall vehicle lightweighting.

Integrated Mounting Interfaces

Pre-designed clips, positioning holes, and mounting bases allow direct and precise integration with center display modules, infotainment frames, and interior trim panels, simplifying assembly and reducing part count.

Enhanced Anti-Vibration Design

Topology optimization and reinforced rib layout improve impact resistance and vibration durability, ensuring stable performance under complex road conditions.

High-Precision Positioning Reference

Critical mounting surfaces and holes are CNC-machined to guarantee accurate alignment, preventing loosening or displacement of the center display and improving user interaction quality.

Performance Advantages

Lightweight & Efficient

Honeycomb structure achieves effective weight reduction while meeting automotive structural requirements.

Simplified Assembly

Integrated design reduces the number of components, lowering assembly complexity and cost.

Outstanding Reliability

Validated through rigorous vibration, impact, and durability testing to ensure stable performance throughout the vehicle lifecycle.

Customization Capability

Custom-developed according to different vehicle models, display sizes, layouts, and interior styles, compatible with mainstream infotainment platforms.

Typical Applications

Widely used in new energy vehicles and intelligent connected vehicles, including:

Automotive center display screens

Passenger-side entertainment displays

Smart cockpit and infotainment structural systems

This integrated die-cast bracket plays a critical role in enhancing structural stability, assembly efficiency, and user experience in modern vehicle interiors.