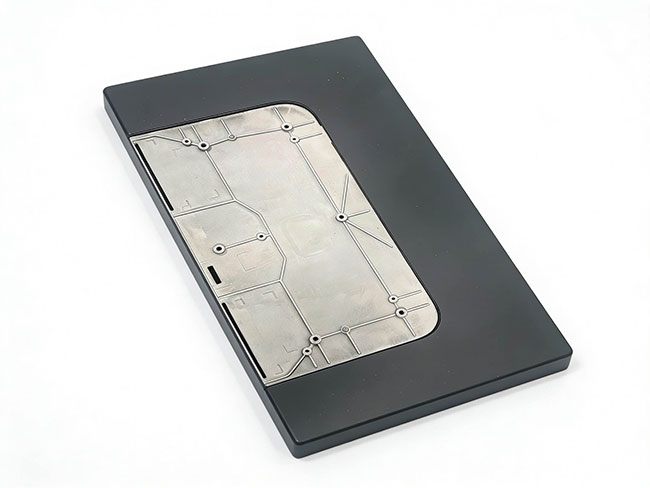

Automotive Energy Storage / In-Vehicle System Aluminum Alloy Integrated Base Plate Die-Cast Component

| Item | Specification |

|---|---|

| Product Name | Integrated Aluminum Die Casting Base Plate |

| Application | EV Energy Storage / IVI Systems |

| Material | Aluminum Alloy (ADC12 / A380) |

| Manufacturing Process | High Pressure Die Casting |

| Post Processing | CNC Machining |

| Structural Function | Mounting, Support, Heat Spreading |

| Dimensional Tolerance | ±0.05 mm (Critical Areas) |

| Thermal Function | Auxiliary Heat Dissipation |

| Surface Treatment | As-cast / E-Coating / Powder Coating (Optional) |

| Vibration Resistance | Automotive Grade |

| Quality Standard | IATF 16949 / ISO 9001 |

| Customization | OEM / ODM Supported |

Description

Specifically designed for new energy vehicle energy storage systems or smart cockpit infotainment systems, this aluminum alloy integrated mounting base plate utilizes an integrated die-casting process. It provides high-precision structural support, mounting positioning, and auxiliary heat dissipation for battery management modules, control units, or core infotainment components, serving as a core foundational part ensuring the stable and reliable operation of in-vehicle electronic systems.

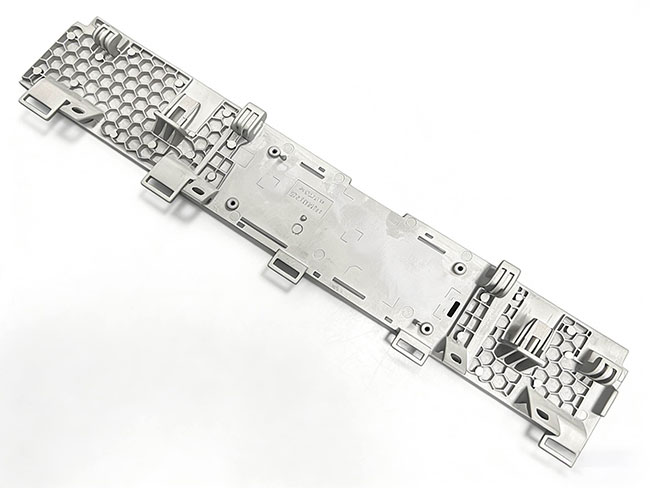

Core Materials & Processes

Material: High-strength aluminum alloys (e.g., ADC12/A380) selected for lightweighting, vibration resistance, and thermal conductivity.

Process: High-pressure die-casting for monolithic forming, complemented by precision CNC machining to ensure dimensional accuracy of complex mounting holes and module interfaces.

Key Design Highlights

Integrated Module Layout: Features multiple square and irregular mounting positions for direct integration of Battery Management Units (BMUs), power modules, sensors, or core infotainment boards, enabling high-density integration.

High-Precision Mounting Interfaces: Pre-set threaded holes, locating pins, and snap-fits ensure precise module alignment, meeting automotive-grade assembly tolerance requirements.

Thermal Assistance Design: The flat aluminum alloy base plate functions as a heat spreader, rapidly dissipating module operating heat to enhance system stability.

Weight Reduction & Strength Optimization: Topology-optimized design reduces component weight while maintaining structural integrity, contributing to vehicle lightweighting.

Performance Advantages

High Integration: Significantly reduces component count, simplifies assembly processes, and lowers vehicle cost and weight.

Robust Reliability: Withstands rigorous vibration, shock, and endurance testing to adapt to complex driving conditions.

Efficient Thermal Management: Metal construction and flat structure enhance heat dissipation, preventing performance degradation from module overheating.

Customizable Adaptation: Tailored development for different vehicle models' energy storage systems or infotainment architectures, compatible with mainstream automotive electronics platforms.

Application Scenarios

Widely used in new energy vehicles for energy storage battery packs, power control systems, and smart cockpit infotainment systems, serving as a key component for enhancing the integration, reliability, and user experience of in-vehicle electronic systems.