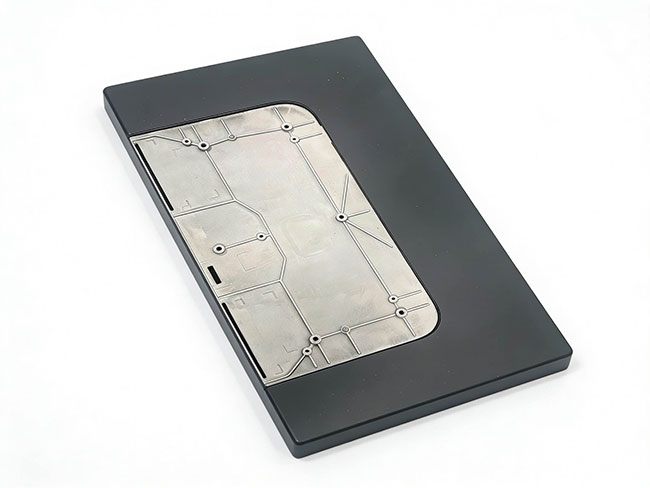

Surface Treatment Methods for Die-Cast Aluminum Alloys

Time :2025-10-31 Hits:1080

As is well known, die-cast aluminum alloys differ in composition from extruded aluminum profiles. Consequently, their surface treatment methods also vary. This often leads to uncertainty in selecting appropriate surface treatments for die-cast aluminum alloys. Today, Jinhongfeng Die-Casting Company introduces several surface treatment methods for die-cast aluminum alloys, hoping to provide some inspiration.

Numerous surface treatment methods exist for die-cast aluminum alloys. The selection of processing techniques depends on the product's quality requirements. Currently, the most widely applicable surface treatment methods are:

1. If the surface quality standard requires the natural metallic color of the aluminum alloy, polishing or passivation for corrosion protection can be employed.

2. If the surface does not require the natural metallic color of the aluminum alloy, cleaning or passivation for corrosion protection can be applied.

3. If the surface requires various decorative colors, methods such as cleaning, passivation, spraying, or electrophoresis can be used.

4. If the surface requires a protective metal coating, cleaning followed by electroplating can be employed.

5. For products with stringent corrosion resistance requirements, cleaning, activation, stainless steel passivation, or a sequence of stainless steel passivation followed by sealing and spraying can be employed;

6. In the current industry, conductive passivation methods are also used for die-cast aluminum alloy treatment. Presently, most applications utilize the above six die-cast aluminum alloy surface treatment methods. I believe technological advancements will lead to the emergence of more surface treatment solutions for die-cast aluminum alloys.

The above summarizes the surface treatment methods for die-cast aluminum alloys compiled by Shenzhen Jinhongfeng Arts & Crafts Co., Ltd. We hope this provides valuable assistance.

PREV:Thermal Performance of Aluminum Alloy Die-Cast Lamp Housings

NEXT:What are the challenges in the die-casting process for zinc alloy components?

Related News

- A Strategic Guide to Die-Casting Material Selection: Magnesium vs. Aluminum

- Enhancing EV Infrastructure: Why High-Precision Die Casting is Indispensable for NEV Charging Components

- Enchuang Technology: Professional Aluminum Alloy Die Casting Solutions

- Zinc Alloy Die Casting: Technology, Production & Advantages

- What are the challenges in the die-casting process for zinc alloy components?

- Surface Treatment Methods for Die-Cast Aluminum Alloys

- Thermal Performance of Aluminum Alloy Die-Cast Lamp Housings

- How Zinc Alloy Die Casting Delivers High Precision in Modern Manufacturing

Related Product

-

Automotive Power Amplifier / Amplifier Module Die-Cast Heat Sink Housing Die-Casting Factory

-

Die-Cast Housing Factory for Automotive Electronic Control Units (ECUs)

-

Automotive Energy Storage / In-Vehicle System Aluminum Alloy Integrated Base Plate Die-Cast Component

-

VC Vapor Chamber Integrated Housing for Automotive Center Display