Enhancing EV Infrastructure: Why High-Precision Die Casting is Indispensable for NEV Charging Components

Time :2026-01-13 Hits:1014

As the global automotive industry accelerates its transition to New Energy Vehicles (NEVs), the demand for robust, reliable, and high-performance charging infrastructure has reached unprecedented heights. At the core of this transformative ecosystem lies a pivotal manufacturing process: High-Pressure Die Casting (HPDC).

Boasting 24 years of specialized expertise in zinc, aluminum, and magnesium alloy die casting, Jinyuanfu has emerged as a trusted strategic partner for Tier 1 suppliers and OEM manufacturers across the NEV sector. This article delves into how precision die casting is redefining the performance and durability of EV charging accessories.

1. Superior Thermal Management for High-Power Charging

Modern EV fast chargers generate substantial heat during peak operation, which poses a critical threat to sensitive electronic components. Aluminum alloys—specifically ADC12 and A380—are the material of choice for charger navigation radiators and power converter enclosures, thanks to their exceptional thermal conductivity.

At Jinyuanfu, we leverage advanced die-casting simulation technologies to optimize the design of heat sink fins. This precision engineering ensures that electronics maintain stable operating temperatures even under full-load high-power delivery, directly extending the service life of charging stations and guaranteeing consistent performance over time.

2. Durability & Aesthetics Integrated in Charging Gun Housings

The charging gun serves as the primary user touchpoint for EV charging systems, requiring a perfect balance of impact resistance, weatherproofing, and ergonomic design.

Zinc Alloy Casting: Ideal for high-end charging connectors, zinc alloy delivers a premium, substantial handfeel, supports superior surface finishing (such as electroplating and powder coating), and provides inherent EMI shielding to protect signal integrity.

Magnesium Alloy: For ultra-lightweight portable chargers, magnesium alloy offers the industry-leading strength-to-weight ratio, enabling easy portability without compromising structural durability.

3. Precision Engineering for IP67 Weatherproofing

Charging infrastructure operates in harsh outdoor environments—from freezing rain and snow to scorching sunlight and dust storms. Our integrated CNC precision machining capabilities ensure that every die-cast component meets ultra-tight tolerances of ±0.01mm.

This level of precision is non-negotiable for achieving IP67 or even IP68 ingress protection ratings, effectively sealing high-voltage internal circuits against dust and moisture intrusion, and safeguarding device safety and reliability in extreme conditions.

4. The Jinyuanfu Advantage: 24 Years of Uncompromising Excellence

What sets Jinyuanfu apart in the fiercely competitive automotive die-casting market?

Material Versatility: We are among the rare manufacturers capable of mastering zinc, aluminum, and magnesium alloy die casting under a single roof, providing clients with flexible, one-source material solutions.

IATF 16949 Certified: Our quality management systems are fully aligned with global automotive industry standards, ensuring zero-defect production and seamless compliance with client supply chain requirements.

Full Lifecycle Support: From mold flow analysis and custom tooling design, to CNC precision machining and comprehensive surface treatments (powder coating, anodizing, electroplating), we deliver a seamless one-stop solution that streamlines our clients’ production workflows.

Conclusion: Partnering for a Greener Tomorrow

The shift to sustainable mobility demands components that are not only high-performance and durable, but also eco-friendly and recyclable. High-pressure die casting stands as a sustainable manufacturing solution—utilizing 100% recyclable alloys and minimizing material waste through near-net-shape production, which reduces post-processing and carbon footprint.

As we stride toward 2026 and beyond, Jinyuanfu remains steadfast in supporting the global NEV supply chain, combining 24 years of proven expertise with unwavering precision and passion to power the future of green transportation.

PREV:Enchuang Technology: Professional Aluminum Alloy Die Casting Solutions

NEXT:A Strategic Guide to Die-Casting Material Selection: Magnesium vs. Aluminum

Related News

- A Strategic Guide to Die-Casting Material Selection: Magnesium vs. Aluminum

- Enhancing EV Infrastructure: Why High-Precision Die Casting is Indispensable for NEV Charging Components

- Enchuang Technology: Professional Aluminum Alloy Die Casting Solutions

- Zinc Alloy Die Casting: Technology, Production & Advantages

- What are the challenges in the die-casting process for zinc alloy components?

- Surface Treatment Methods for Die-Cast Aluminum Alloys

- Thermal Performance of Aluminum Alloy Die-Cast Lamp Housings

- How Zinc Alloy Die Casting Delivers High Precision in Modern Manufacturing

Related Product

-

Automotive Power Amplifier / Amplifier Module Die-Cast Heat Sink Housing Die-Casting Factory

-

Die-Cast Housing Factory for Automotive Electronic Control Units (ECUs)

-

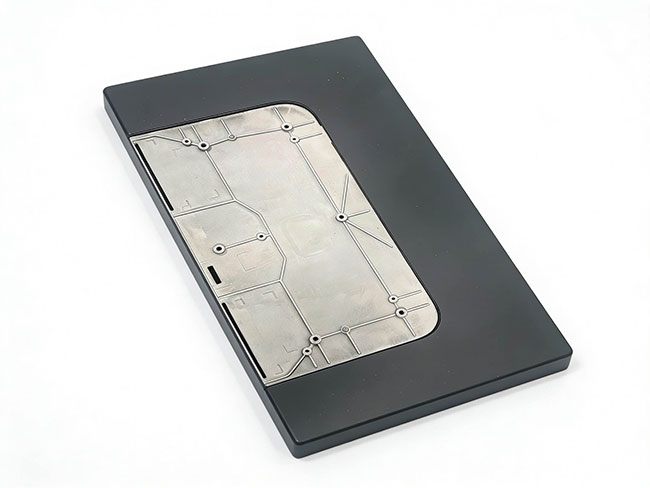

Automotive Energy Storage / In-Vehicle System Aluminum Alloy Integrated Base Plate Die-Cast Component

-

VC Vapor Chamber Integrated Housing for Automotive Center Display