Zinc Alloy Die Casting: Technology, Production & Advantages

Time :2026-01-02 Hits:1015

Overview of Zinc Alloy Die Casting

Die casting is a precision metal forming process defined by the use of a steel mold cavity to exert high pressure on molten metal. The core process involves heating metal to a molten state, rapidly filling the mold cavity at high speed and under high pressure, and then cooling and solidifying the metal under sustained pressure to form the desired part. In simple terms, the process revolves around three key elements: high-quality metal materials, precise high-pressure application, and mold-based casting.

Enchuang Technology Co., Ltd. is a professional provider of zinc alloy die casting solutions, boasting over 40 sets of zinc alloy die casting machines with tonnages ranging from 20T to 200T. We cater to global customers with comprehensive zinc die casting services, focusing on two primary die casting materials: Zinc Alloy 3# (Zamak 3# / ZnAl4 / ZP0400 / ZDC1) and Zinc Alloy 5# (Zamak 5# / ZnAl4Cu1 / ZP0410 / ZDC2). Both materials are processed via hot chamber die casting, a technology renowned for its efficiency in zinc alloy processing.

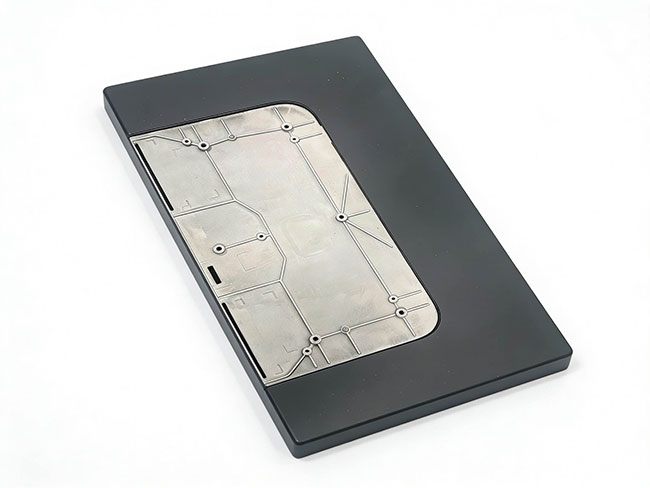

To further enhance production capabilities, we have introduced high-precision four-axis multi-slide high-speed die casting machines. These advanced machines enable high-speed, efficient, and high-yield production with exceptional precision. The parts produced feature minimal burrs, reducing the need for secondary processing and significantly improving production efficiency. A typical application of these high-precision parts is the housing of automotive Fakra connectors, where dimensional accuracy and surface quality are critical to performance.

Zinc Alloy Die Casting Production Capabilities & Advantages

Zinc alloy exhibits excellent die casting performance, making it ideal for manufacturing parts with complex shapes, deep cavities, and ultra-thin walls (wall thickness can be as low as 0.25-0.5mm). Despite their intricate designs and thin structures, these parts maintain tight dimensional tolerances, meeting the strict precision requirements of various industrial applications.

Another notable advantage of zinc alloy die castings is their compatibility with a wide range of surface treatments, with particularly excellent adhesion for plating processes (such as chrome plating, nickel plating, and zinc plating). This versatility allows the parts to achieve diverse aesthetic and functional effects, adapting to different environmental and application needs.

High-Pressure Die Casting (HPDC), the core technology we adopt, offers unparalleled advantages in mass production. It can efficiently manufacture both large and small-sized zinc alloy parts at high speed, ensuring consistent production quality and high throughput. Beyond efficiency, the HPDC process delivers parts with superior surface finish (reducing post-processing costs), excellent material uniformity (enhancing structural stability), and optimum mechanical properties (such as high strength and wear resistance). These characteristics make zinc alloy die castings widely applicable in automotive, electronics, telecommunications, and consumer goods industries, among others.

PREV:What are the challenges in the die-casting process for zinc alloy components?

NEXT:Enchuang Technology: Professional Aluminum Alloy Die Casting Solutions

Related News

- A Strategic Guide to Die-Casting Material Selection: Magnesium vs. Aluminum

- Enhancing EV Infrastructure: Why High-Precision Die Casting is Indispensable for NEV Charging Components

- Enchuang Technology: Professional Aluminum Alloy Die Casting Solutions

- Zinc Alloy Die Casting: Technology, Production & Advantages

- What are the challenges in the die-casting process for zinc alloy components?

- Surface Treatment Methods for Die-Cast Aluminum Alloys

- Thermal Performance of Aluminum Alloy Die-Cast Lamp Housings

- How Zinc Alloy Die Casting Delivers High Precision in Modern Manufacturing

Related Product

-

Automotive Power Amplifier / Amplifier Module Die-Cast Heat Sink Housing Die-Casting Factory

-

Die-Cast Housing Factory for Automotive Electronic Control Units (ECUs)

-

Automotive Energy Storage / In-Vehicle System Aluminum Alloy Integrated Base Plate Die-Cast Component

-

VC Vapor Chamber Integrated Housing for Automotive Center Display