Enchuang Technology: Professional Aluminum Alloy Die Casting Solutions

Time :2026-01-02 Hits:1017

Enchuang Technology Co., Ltd. is a professional manufacturer dedicated to aluminum alloy die casting, boasting a comprehensive production capacity and rich industry experience. Equipped with over 20 sets of advanced aluminum alloy die casting machines, our production line covers a wide tonnage range from 160T to 1000T, enabling us to fulfill diverse casting requirements for parts of different sizes and complexities. We provide high-quality aluminum die casting services to global customers, with a focus on delivering reliable and customized solutions for various industrial sectors. The main aluminum alloys we adopt for die casting are ADC12 (equivalent to A383) and A380 (also known as ALSi8Cu3, complying with EN-46200 standard), which are widely recognized for their excellent casting performance and mechanical properties, making them ideal materials for high-precision die casting parts.

Compared with zinc alloy, aluminum alloy exhibits distinct performance characteristics that make it a preferred choice for many high-demand applications. The detailed comparative advantages and characteristics are as follows:

Lightweight with High Strength: Aluminum alloy features a lower density (approximately 2.7g/cm³) compared to zinc alloy (about 6.6g/cm³), contributing to significant weight reduction of finished parts. Meanwhile, it offers higher specific strength, making the castings more durable and capable of withstanding greater loads under the same weight condition.

Superior Mechanical Properties: It possesses excellent comprehensive mechanical properties, particularly outstanding impact toughness. This enables aluminum alloy die casting parts to maintain structural integrity and stability even in harsh working environments with frequent vibrations or impacts.

Excellent Thermal and Electrical Performance: As an optimal material for heat transfer applications, aluminum alloy has excellent thermal conductivity, which is crucial for parts requiring efficient heat dissipation. Additionally, it exhibits good electrical conductivity and superior machinability, allowing for precise processing and shaping to meet strict dimensional tolerances.

Strong Wear and Corrosion Resistance: The inherent chemical stability of aluminum alloy endows it with good wear and corrosion resistance. After appropriate surface treatment, this performance can be further enhanced, ensuring long-term service life of the castings in humid, corrosive or high-wear environments.

Outstanding Casting Performance: Aluminum alloy demonstrates excellent fluidity during the casting process, enabling it to fill the mold cavity completely even for parts with intricate structures. The castings produced have good surface finish (low surface roughness) and a low tendency for hot cracking, reducing the need for subsequent surface repair and improving production efficiency.

Notable Casting Challenges: It should be noted that aluminum alloy has a relatively large volume shrinkage rate during the solidification process, which makes it prone to forming shrinkage cavities and porosity if the casting process parameters are not properly controlled. Moreover, due to the high casting temperature and the chemical reactivity of aluminum, it has a tendency to stick to the mold, requiring advanced mold design, high-quality mold materials and precise process control to address these issues.

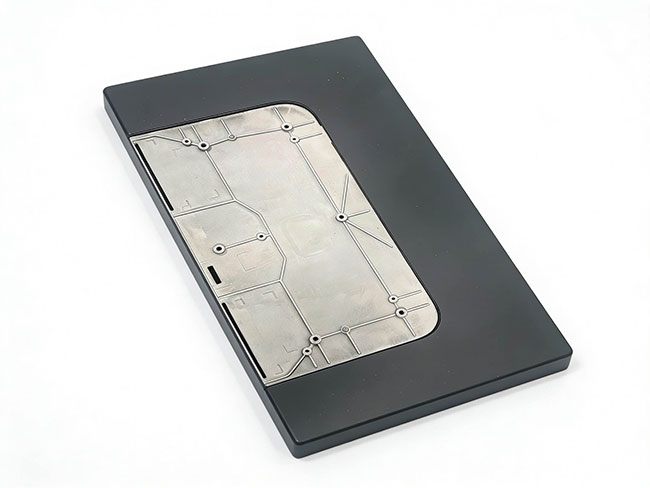

Benefiting from the aforementioned excellent properties, aluminum alloy die casting parts have been widely applied in numerous key industrial fields. Typical applications include heat sinks (for electronic devices, automotive cooling systems, etc.), lightweight metal fittings (for aerospace, marine, and industrial machinery), new energy vehicle components (such as battery housings, motor casings, and inverter shells), power tools (gearboxes, housings), and communication equipment (base station components, router casings). These parts play a critical role in improving product performance, reducing energy consumption, and enhancing structural reliability.

To further enhance the corrosion resistance and surface quality of aluminum die casting parts, Enchuang Technology offers a range of professional surface treatment processes, including zinc-nickel plating, electrophoretic coating (e-coating), and passivation. Our surface-treated products have undergone rigorous salt spray testing, achieving an impressive corrosion resistance of 720 to 1000 hours. This level of performance ensures that the castings can withstand harsh corrosive environments such as marine, industrial pollution, and humid climates, fully meeting the high reliability requirements of customers in various industries. With strict quality control throughout the production and surface treatment processes, we are committed to providing global customers with aluminum alloy die casting parts that combine high precision, excellent performance, and long service life.

Related News

- A Strategic Guide to Die-Casting Material Selection: Magnesium vs. Aluminum

- Enhancing EV Infrastructure: Why High-Precision Die Casting is Indispensable for NEV Charging Components

- Enchuang Technology: Professional Aluminum Alloy Die Casting Solutions

- Zinc Alloy Die Casting: Technology, Production & Advantages

- What are the challenges in the die-casting process for zinc alloy components?

- Surface Treatment Methods for Die-Cast Aluminum Alloys

- Thermal Performance of Aluminum Alloy Die-Cast Lamp Housings

- How Zinc Alloy Die Casting Delivers High Precision in Modern Manufacturing

Related Product

-

Automotive Power Amplifier / Amplifier Module Die-Cast Heat Sink Housing Die-Casting Factory

-

Die-Cast Housing Factory for Automotive Electronic Control Units (ECUs)

-

Automotive Energy Storage / In-Vehicle System Aluminum Alloy Integrated Base Plate Die-Cast Component

-

VC Vapor Chamber Integrated Housing for Automotive Center Display